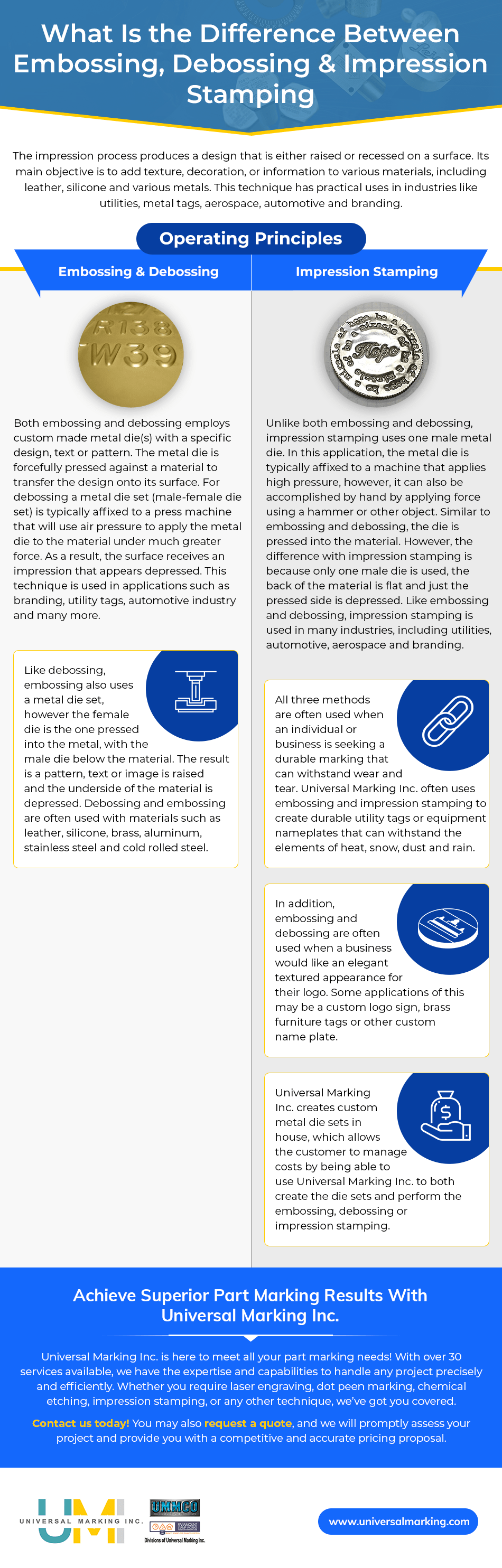

The impression process produces a design that is either raised or recessed on a surface. Its main objective is to add texture, decoration, or information to various materials, including leather, silicone and various metals. This technique has practical uses in industries like utilities, metal tags, aerospace, automotive and branding.

This article will explain the key differences between embossing, debossing and impression stamping and the methods used to create either a raised or depressed impression.

Embossing and Debossing: Operating Principles

Both embossing and debossing employs custom made metal die(s) with a specific design, text or pattern. The metal die is forcefully pressed against a material to transfer the design onto its surface. For debossing a metal die set (male-female die set) is typically affixed to a press machine that will use air pressure to apply the metal die to the material under much greater force. As a result, the surface receives an impression that appears depressed. This technique is used in applications such as branding, utility tags, automotive industry and many more.

Like debossing, embossing also uses a metal die set, however the female die is the one pressed into the metal, with the male die below the material. The result is a pattern, text or image is raised and the underside of the material is depressed. Debossing and embossing are often used with materials such as leather, silicone, brass, aluminum, stainless steel and cold rolled steel.

Impression Stamping: Operating Principles

Unlike both embossing and debossing, impression stamping uses one male metal die. In this application, the metal die is typically affixed to a machine that applies high pressure, however, it can also be accomplished by hand by applying force using a hammer or other object. Similar to embossing and debossing, the die is pressed into the material. However, the difference with impression stamping is because only one male die is used, the back of the material is flat and just the pressed side is depressed. Like embossing and debossing, impression stamping is used in many industries, including utilities, automotive, aerospace and branding.

All three methods are often used when an individual or business is seeking a durable marking that can withstand wear and tear. Universal Marking Inc. often uses embossing and impression stamping to create durable utility tags or equipment nameplates that can withstand the elements of heat, snow, dust and rain.

In addition, embossing and debossing are often used when a business would like an elegant textured appearance for their logo. Some applications of this may be a custom logo sign, brass furniture tags or other custom name plate.

Universal Marking Inc. creates custom metal die sets in house, which allows the customer to manage costs by being able to use Universal Marking Inc. to both create the die sets and perform the embossing, debossing or impression stamping.

Achieve Superior Part Marking Results With Universal Marking Inc.

Universal Marking Inc. is here to meet all your part marking needs! With over 30 services available, we have the expertise and capabilities to handle any project precisely and efficiently. Whether you require laser engraving, dot peen marking, chemical etching, impression stamping, or any other technique, we’ve got you covered.

Contact us today! You may also request a quote, and we will promptly assess your project and provide you with a competitive and accurate pricing proposal.