Description

What are Electro Chemical Etching / Electro Etching / Electrolytic Etching Services?

Electro Chemical Etching (also referred to as Electro Etching, Chemical Etching, Electro Marking, or Electrolytic Etching) is the operation of pressing an electrolyte-soaked electrode onto a stencil that is placed over a metal part. The electric current from the electrode dissolves the metal material under the stencil, thus creating the desired mark. The depth of the electro chemically etched mark will increase based on the length of time the electrode is pressed through the stencil onto the metal part.

Advantages

Pros of Electro Chemical Etching / Electro Etching / Electrolytic Etching Services

- No stress levied on the part being chemically etched / electroetched

- Can easily burn through heat treated material (over 60 Rockwell)

- Does not weaken the physical or chemical properties of the metal part

- Low setup cost and low per unit charge for surface electro etching

- Very sharp and crisp edges on chemically etched marks at depths up to 0.006"

Features

Features of Electro Chemical Etching / Electro Etching / Electrolytic Etching Services

- Since 1975, we have performed Electro Chemical Etching / Electro Marking Services for over 25 different industries (including Aerospace, Military, Defense, and Medical)

- Conveniently located in Paramount, California (15 minutes from Downtown Los Angeles)

- Ability to electro chemically etch very shallow (<0.001”) or very deep (0.006”)

- Ability to electro chemically etch very light/frosted mark (DC Current) or very dark mark (AC Current)

- Ability to make chemical etching stencils in-house. Simply email your logo or text and we will take care of the rest.

- Ability to electro chemically etch stainless steel, aluminum (anodized & bare), titanium, and many more metals that are both heat-treated and non-heat-treated

- Common Part Marking Specifications for Electrochemical Etching include Spec SAE AS478, Spec MIL-STD-130, Boeing Spec BAC5307, Parker Aerospace Spec BPS 4106, General Electric Spec P23TF3, & Sikorsky Spec SS8798

Electro Chemical Etching / Electro Etching / Electrolytic Etching Services

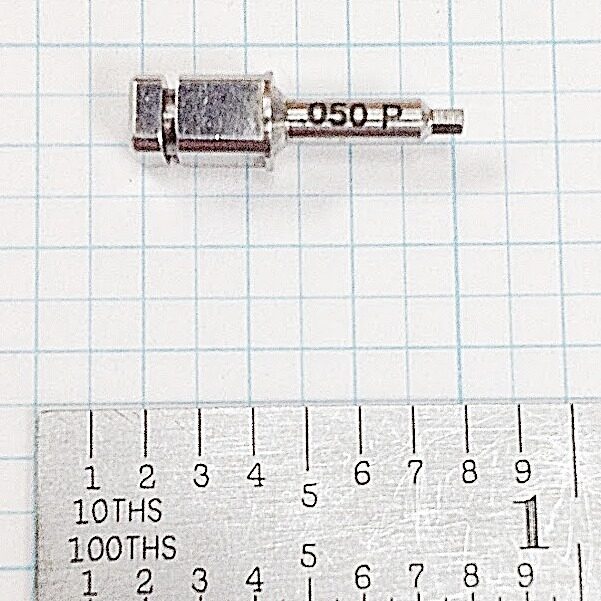

Electro Chemical Etching / Electro Etching / Electrolytic Etching Shallow Marks

Electro Chemical Etching / Electro Etching / Electrolytic Etching Services

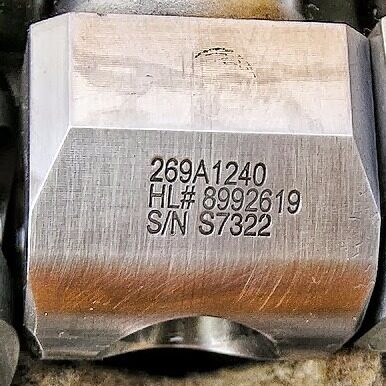

Electro Chemical Etching / Electro Etching / Electrolytic Etching Deep Marks

Complete our simple Request For Quotation form and a Sales Professional will submit a customized quote to you ASAP.

Complete our simple Request For Quotation form and a Sales Professional will submit a customized quote to you ASAP.

Call (562) 634-6300 | Toll-Free (800) 803-8333 | Fax (562) 633-0600 | 14053 Orange Ave. Paramount, CA 90723 | Monday - Friday 7:00 a.m. - 4:00 p.m.

Call (562) 634-6300

Toll-Free (800) 803-8333

Fax (562) 633-0600

14053 Orange Ave.

Paramount, CA 90723

Monday - Friday

7:00 a.m. - 4:00 p.m.