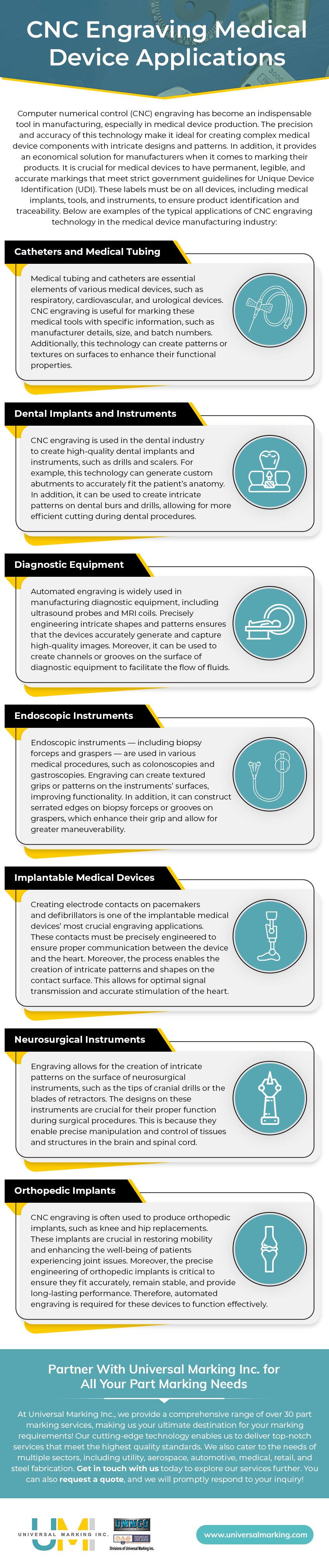

Computer numerical control (CNC) engraving has become an indispensable tool in manufacturing, especially in medical device production. The precision and accuracy of this technology make it ideal for creating complex medical device components with intricate designs and patterns. In addition, it provides an economical solution for manufacturers when it comes to marking their products.

It is crucial for medical devices to have permanent, legible, and accurate markings that meet strict government guidelines for Unique Device Identification (UDI). These labels must be on all devices, including medical implants, tools, and instruments, to ensure product identification and traceability.

Below are examples of the typical applications of CNC engraving technology in the medical device manufacturing industry:

1. Catheters and Medical Tubing

Medical tubing and catheters are essential elements of various medical devices, such as respiratory, cardiovascular, and urological devices. CNC engraving is useful for marking these medical tools with specific information, such as manufacturer details, size, and batch numbers. Additionally, this technology can create patterns or textures on surfaces to enhance their functional properties.

2. Dental Implants and Instruments

CNC engraving is used in the dental industry to create high-quality dental implants and instruments, such as drills and scalers. For example, this technology can generate custom abutments to accurately fit the patient’s anatomy. In addition, it can be used to create intricate patterns on dental burs and drills, allowing for more efficient cutting during dental procedures.

3. Diagnostic Equipment

Automated engraving is widely used in manufacturing diagnostic equipment, including ultrasound probes and MRI coils. Precisely engineering intricate shapes and patterns ensures that the devices accurately generate and capture high-quality images. Moreover, it can be used to create channels or grooves on the surface of diagnostic equipment to facilitate the flow of fluids.

4. Endoscopic Instruments

Endoscopic instruments — including biopsy forceps and graspers — are used in various medical procedures, such as colonoscopies and gastroscopies. Engraving can create textured grips or patterns on the instruments’ surfaces, improving functionality. In addition, it can construct serrated edges on biopsy forceps or grooves on graspers, which enhance their grip and allow for greater maneuverability.

5. Implantable Medical Devices

Creating electrode contacts on pacemakers and defibrillators is one of the implantable medical devices’ most crucial engraving applications. These contacts must be precisely engineered to ensure proper communication between the device and the heart. Moreover, the process enables the creation of intricate patterns and shapes on the contact surface. This allows for optimal signal transmission and accurate stimulation of the heart.

6. Neurosurgical Instruments

Engraving allows for the creation of intricate patterns on the surface of neurosurgical instruments, such as the tips of cranial drills or the blades of retractors. The designs on these instruments are crucial for their proper function during surgical procedures. This is because they enable precise manipulation and control of tissues and structures in the brain and spinal cord.

7. Orthopedic Implants

CNC engraving is often used to produce orthopedic implants, such as knee and hip replacements. These implants are crucial in restoring mobility and enhancing the well-being of patients experiencing joint issues. Moreover, the precise engineering of orthopedic implants is critical to ensure they fit accurately, remain stable, and provide long-lasting performance. Therefore, automated engraving is required for these devices to function effectively.

Partner With Universal Marking Inc. for All Your Part Marking Needs

At Universal Marking Inc., we provide a comprehensive range of over 30 part marking services, making us your ultimate destination for your marking requirements! Our cutting-edge technology enables us to deliver top-notch services that meet the highest quality standards. We also cater to the needs of multiple sectors, including utility, aerospace, automotive, medical, retail, and steel fabrication.

Get in touch with us today to explore our services further. You can also

request a quote, and we will promptly respond to your inquiry!