Description

When products need to be marked with a logo, text, graphical information, or other images, many manufacturers turn to silk screening. This process is compatible with a variety of materials like fabric, glass, metal, plastic, and wood. It creates vibrant, colorful images that are crisp and clear and don’t wear away over time.

Silk screening starts with a stenciled graphic on a mesh fabric, such as nylon, polyester, silk, vinyl, or stainless steel mesh. Ink is pressed through the screen with a rubber blade, transferring the image onto a new surface. Modern silk screening processes can incorporate multiple colors by using multiple layers of screens to produce the image.

This technique is a popular and cost-effective way to add decorative, informational, or branding elements to all different sorts of products. At Universal Marking, we serve many different industries including commercial, aerospace, defense, arts and entertainment, and technology markets. Learn more about the benefits and applications to determine if silk screening is the right choice for your next project.

Benefits of Silk Screening

Silk screening is a stand-out printing method that creates beautiful, highly detailed images for decorative, commercial, and industrial applications. Consider these benefits:

Versatility

Silk screening offers virtually limitless design freedom to create any image or message.The silk screening process is suitable for many materials, including fabric, glass, metal, plastic, and wood. Both text and images can be reproduced with great clarity, even when multiple colors are used.

Durability

Silk screen printed graphics last for years, even through exposure to UV radiation, wear and tear, and the elements. This is because the ink is deposited heavily during the printing process, resulting in a durable layer of ink on the finished product that does not wear away like thinly printed messages.

Professional screen printing services can also be used to apply additives or coatings that protect the ink and images from moisture, chemical exposure, UV radiation, and scratches.

Colors Vibrancy

Silk screen inks are bold and resist fading and becoming dull over time. The process works just as well with multiple colors as with a single color because a new mesh screen is created for each one. This ensures each color is deposited accurately and with clean, crisp lines.

Cost-Effectiveness

Even though silk screened images can be complex and colorful, it remains remarkably cost-effective. Once the initial setup and screens are complete, printers can produce each print at a low per-unit cost. Replacement components and tools for this printing method are also budget-friendly, so they contribute less to overall project pricing than some methods. It is also fast and compatible with automation technology, which further lowers production expense.

Exceptional Speed and Efficiency

The actual printing process is quick, and screens can be used over and over with little time between prints. As a result, orders can often be completed with short turnaround times to meet deadlines.

Straightforward Processes

Both manual and automated silk screen printing are simple to set up, carry out, and systematize for a streamlined and efficient workflow.

Applications for Silk Screening

Because silk screening is so versatile, it is used widely for a range of products and parts. It is a standard printing method for many types of consumer goods, commercial tags and marketing materials, and industrial labels or signs. At Universal Marking, some of the applications for which we use silk screening include:

- Clothing designs.

- Displays.

- Medical devices.

- Merchandise.

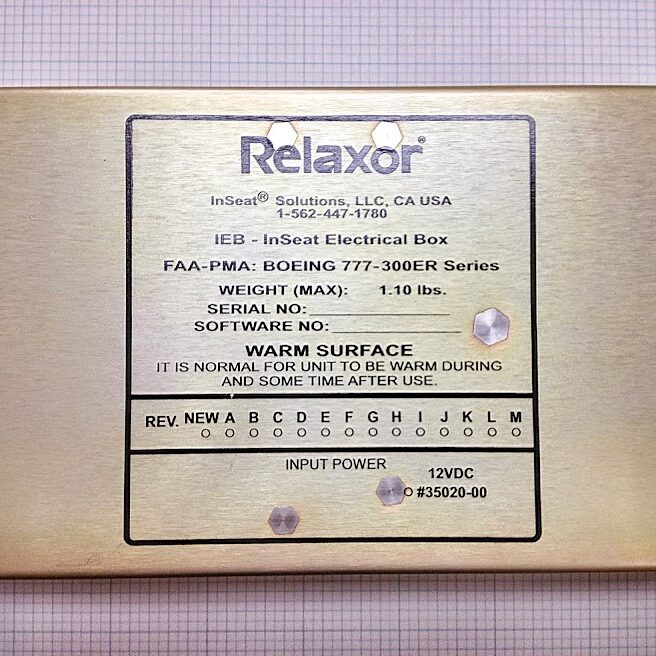

- Product labels and tags.

- Signage.

- Sporting goods.

- Textiles and fabrics.

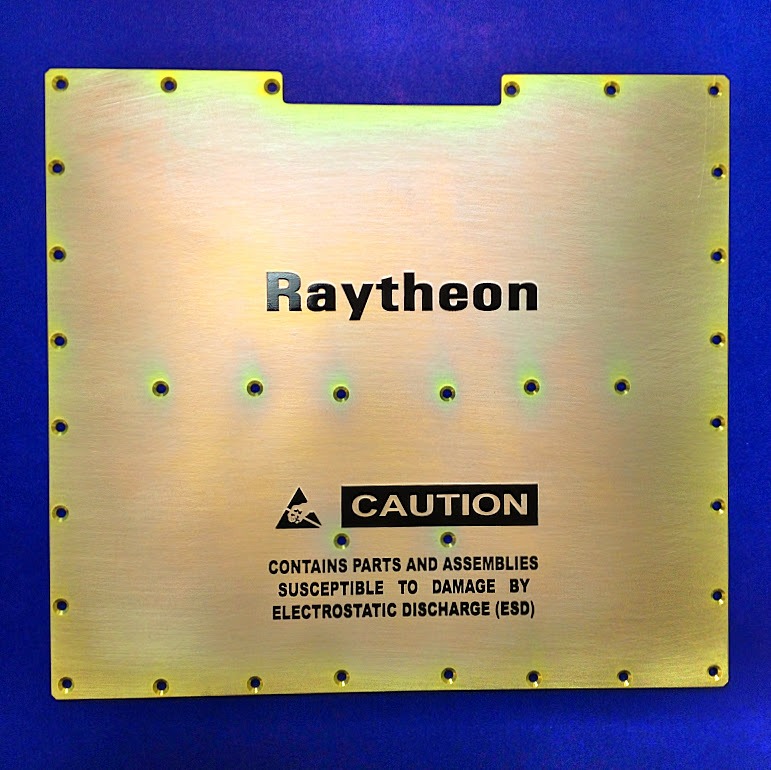

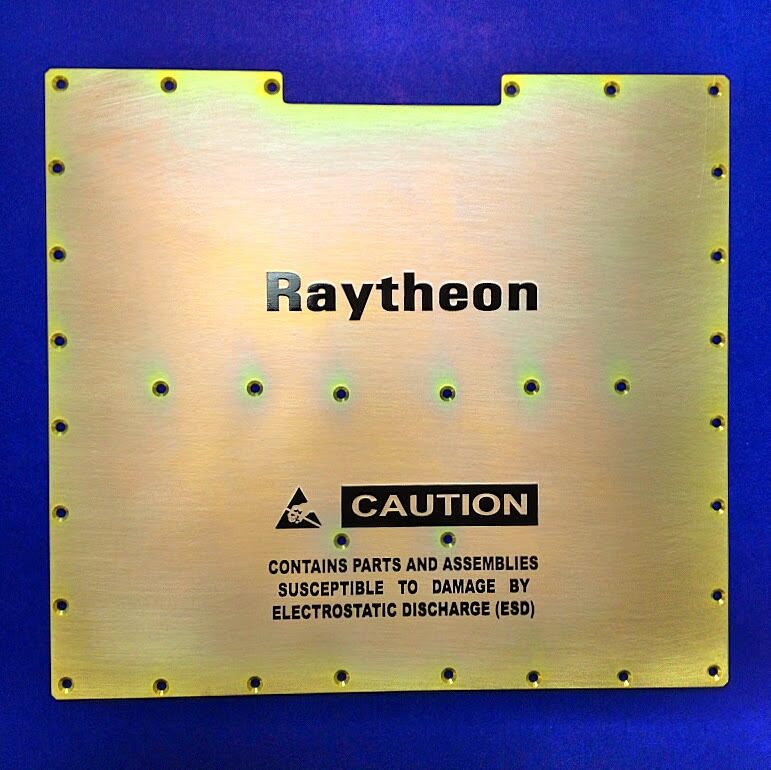

- Aerospace parts.

- Circuit boards.

- Control panels.

- Telecommunications equipment.

Contact Universal Marking for Your Silk Screening Needs

From highly clear, accurate reproductions of text and images for industrial safety equipment to detailed artwork for beverage bottle wraps and beyond, silk screening is an excellent choice. It captures intricate design features and produces vivid, crisp images for products at scale. Universal Marking Inc. specializes in high-quality part marking services, including silk screen printing, on a range of materials and product types. We bring over five decades of experience in metal marking and excellent customer service to every project.

Universal Marking serves customers worldwide with 30 different marking and printing services to meet the needs of the aerospace, military and defense, retail, automotive, medical equipment, recreation, and other industries. We are AS9003-approved and ITAR-registered, and committed to creating detailed markings that comply with industrial regulations, branding and marketing designs, and everything in between.

Contact us today to learn more about our silk screen printing capabilities and to discuss your next project, or request a quote for pricing details.

Advantages

Pros of Silk Screening / Screen Printing Services

- Low pressure applied to marking area

- Variety of inks can be used

- Can be applied to many different materials such as metal, plastic, wood, glass, and ceramics

Features

Features of Silk Screening / Screen Printing Services

- Ability to produce high-run and low-run jobs

- Wide range of colors and the ability to use virtually any color per a customer’s specification

- Common Part Marking Specifications for Silk Screening / Screen Printing include Boeing Spec BAC5307 and Parker Aerospace Spec BPS 4106

Silk Screening / Screen Printing Services

Silk Screening / Screen Printing

Complete our simple Request For Quotation form and a Sales Professional will submit a customized quote to you ASAP.

Complete our simple Request For Quotation form and a Sales Professional will submit a customized quote to you ASAP.

Call (562) 634-6300 | Toll-Free (800) 803-8333 | Fax (562) 633-0600 | 14053 Orange Ave. Paramount, CA 90723

Monday - Friday 7:00 a.m. - 4:00 p.m.

Call (562) 634-6300

Toll-Free (800) 803-8333

Fax (562) 633-0600

14053 Orange Ave.

Paramount, CA 90723

Monday - Friday

7:00 a.m. - 4:00 p.m.