- Long lasting mark

- Low pressure applied to marking area

- High contrast mark

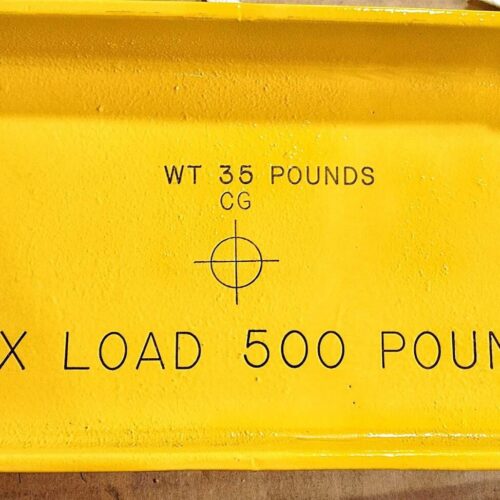

Description

What are Ink Marking / Rubber Stamping / Ink Stamping Services?

Ink Marking is the process of a custom-made rubber stamp dipping into ink and then stamping onto a part. In many cases, UMMCO will apply a clear polyurethane coating to the mark to ensure the permanency of the ink mark.

Advantages

Pros of Ink Marking / Rubber Stamping / Ink Stamping Services

Features

Features of Ink Marking / Rubber Stamping / Ink Stamping Services

- Capability of manufacturing custom-made stamps in-house, which reduces customer costs

- Ability to serialize part numbers, manufacturing numbers, cage codes, etc.

- Access to, and strong knowledge of, many inks called out for in many Aerospace, Military, and Industrial Specifications

- Access to many two-part epoxy inks which provide for greatly reduced drying times

- Ability to apply clear polyurethane coat to maximize the life of the mark

- i. Common Part Marking Specifications for Ink Marking / Ink Stamping include Spec MIL-STD-130, Boeing Spec BAC5307, Parker Aerospace Spec BPS 4106, General Electric Spec P23TF3, & Sikorsky Spec SS8798

Ink Marking

Ink Marking / Rubber Stamping / Ink Stamping Services

Rubber Stamping

Ink Marking / Rubber Stamping / Ink Stamping Services

Need to discuss your custom part marking job?

Our Sales Professionals are ready to help you.

Contact us at 800.803.8333 or info@universalmarking.com